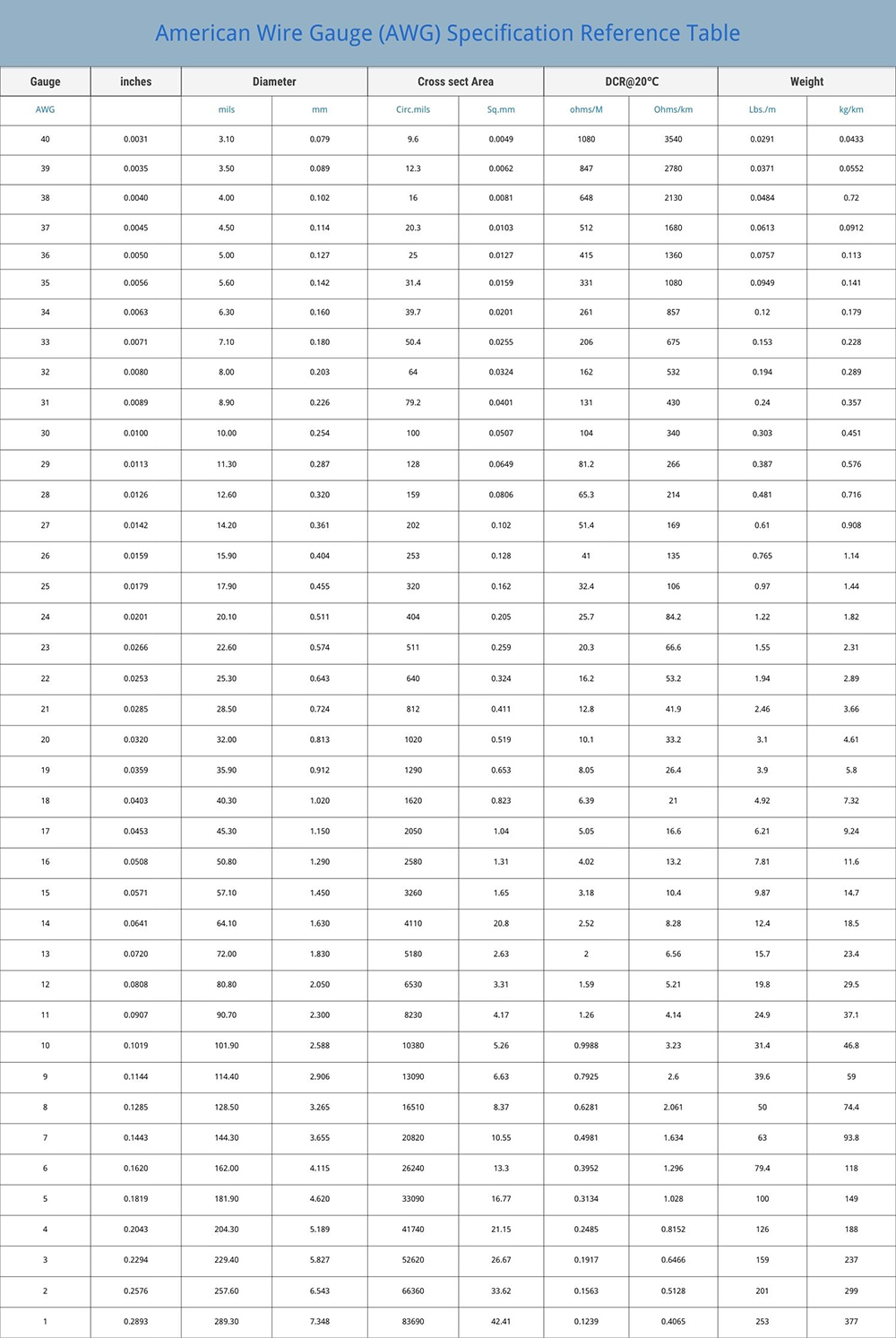

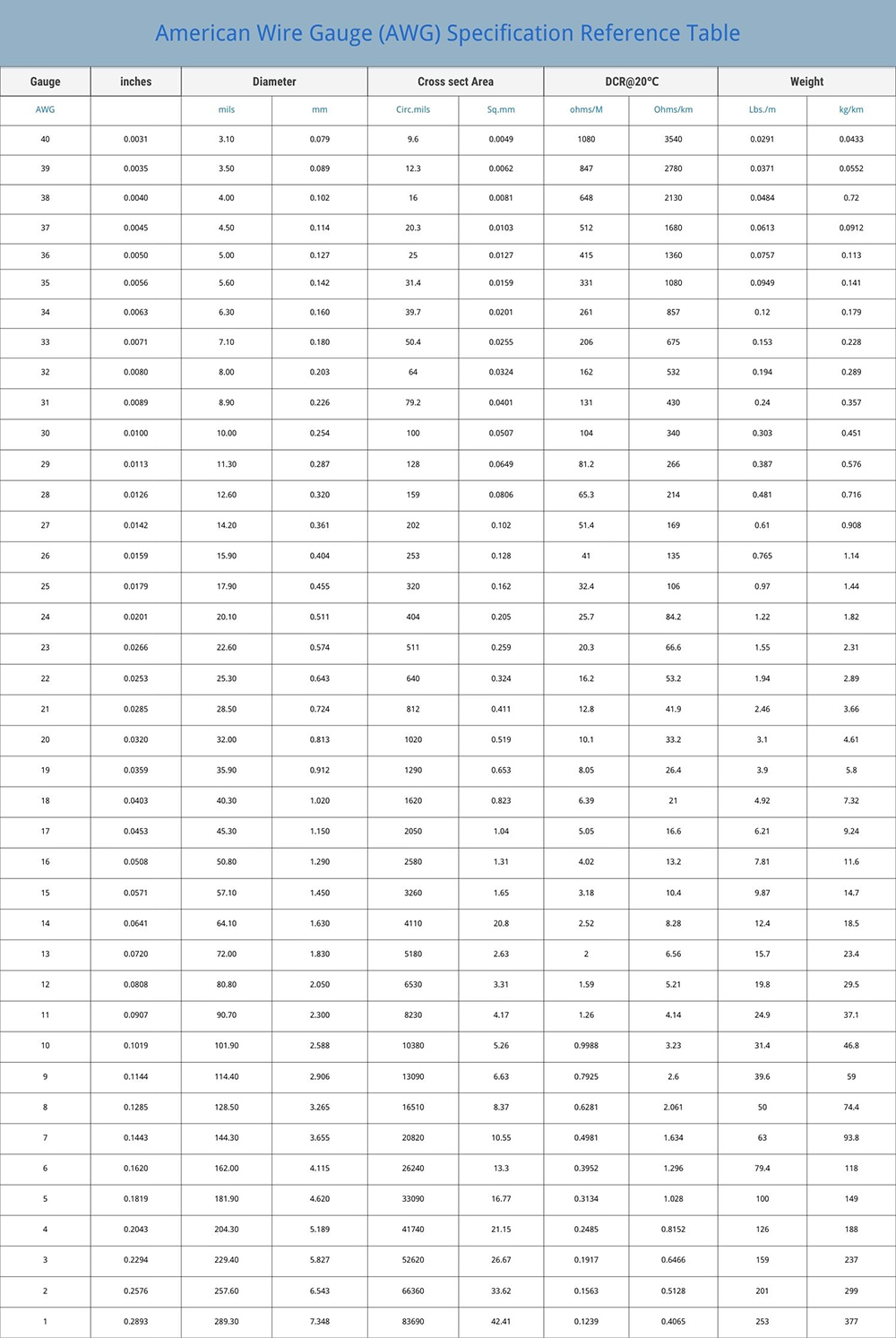

American Wire Gauge (AWG) Specification Reference Table

In electrical engineering, electronics manufacturing, and wire harness design, the American Wire Gauge (AWG) is the core standard for defining the size and performance of conductors. The *AWG Parameter Comparison Table* is a practical handbook that compiles key information about different AWG conductor sizes, useful for engineers selecting materials and beginners learning about conductors. Below is a brief explanation of the table's core content and usage.

I. Understanding the AWG Parameter Table: What Exactly is it?

AWG is a conductor specification standard invented in North America and is now widely used in the global electronics, automotive, and aerospace industries. This parameter table organizes the "physical examination data" (such as thickness, resistance, and weight) of the conductors corresponding to each AWG number, making the originally abstract standard easy to understand.

A key characteristic of AWG is that the smaller the number, the thicker the conductor and the greater the current it can carry (stronger current-carrying capacity); the larger the number, the thinner the conductor and the weaker the current-carrying capacity. For example, AWG 20 is thicker than AWG 24 and can carry more current. This table clearly explains this relationship with specific data, making it easy for everyone to quickly find the right wire.

II. Core Parameters: These 3 Types Are Enough

A practical AWG parameter table mainly contains 3 types of key information. Understanding them will allow you to handle most scenarios:

1. Basic Dimensions: How Thick is the Wire?

The core data determining whether a wire can be installed in equipment and adapt to wiring requirements is based on two data points:

- AWG Number: The core identifier, ranging from AWG 40 (the thinnest, like a hair) to AWG 0000 (the thickest). AWG 1 to AWG 40 are most commonly used.

- Diameter/Cross-sectional Area: Diameter is usually expressed in millimeters (mm), and cross-sectional area in square millimeters (mm²). Both reflect the wire's thickness; the larger the cross-sectional area, the thicker the wire.

2. Electrical Performance: How Well Does the Wire Conduct?

The key is "DC Resistance at 20℃": This refers to the resistance value per kilometer of wire at room temperature (unit: ohms/km). The lower the resistance, the less energy is lost when current flows, and the higher the conductivity. For example, AWG 12 has lower resistance than AWG 20, resulting in better conductivity.

3. Physical Properties: Wire Weight

This mainly refers to "weight per unit length" (commonly kg/km). This is crucial in industries where weight is critical, such as automotive and aerospace, as it helps engineers calculate the total weight of wiring harnesses and avoid overweight products.

III. Common Applications

This table isn't just theoretical; it's applicable in many aspects of life and work:

1. Electronic Equipment Design

When designing mobile phones, computers, and routers, engineers rely on it to select wires. For example, if a circuit requires 5-7A of current, consulting the table shows that AWG 20 is just right—it avoids overheating due to thin wires and wastes material due to thick wires.

2. Automotive/Aerospace Wiring Harnesses

Car engine compartments have high temperatures, requiring thicker wires with better heat dissipation (lower AWG numbers); aircraft are weight-sensitive, and consulting the table helps balance wire thickness and weight, ensuring safety without exceeding weight limits.

3. Procurement/Quality Inspection

When purchasing conductors, use the table as an "inspection checklist" to ensure the conductor parameters meet standards. During quality inspection, check the conductor thickness and resistance against the table to avoid purchasing inferior products.

IV. Tips: Avoid These 3 Pitfalls When Using Tables

Pay attention to these 3 points when consulting tables to avoid errors:

- Distinguish between "single-strand" and "multi-strand" conductors: Some tables will label them separately. Their resistance and flexibility differ slightly; choose according to the actual application.

- Consider operating temperature: Table data is mostly for 20℃ ambient temperature. In high-temperature environments, conductor resistance increases and current carrying capacity decreases, requiring appropriate adjustment of specifications.

- Use consistent units: Tables may use different units such as millimeters (mm) and mils (mils). Convert to consistent units before use to avoid calculation errors.

Finally

The AWG parameter comparison table is a "science popularization + practical guide" for conductors. Its core purpose is to help everyone quickly find conductors with "suitable thickness and meeting performance standards." Whether you're a beginner or a hobbyist, understanding its core logic (smaller numbers mean thicker wires) and key parameters will allow you to easily handle common wire selection needs.

EC-6100 Automatic Heat Shrink Tube Cutting Machine EC-6800 Automatic Cutting Machine EC-6100H Automatic Hot Cutting Machine EC-830 Corrugated Tube Cutting Machine EC-6500 Automatic Cable and Tube Cutting Machine EC-810 Automatic Cable Cutting Machine EC-850X Automatic Rotary Cutting Machine EC-821 Corrugated Tube Cutting Machine EC-890 Multifunctional Automatic Cutting Machine EC-870 High-power Automatic Tube Cutting Machine EC-816 Automatic Cutting Machine EC-823 High Speed Cutting Machine EC-805 Automatic Cable Cutting Machine EC-860 Corrugated Tube Cutting Machine EC-830F Automatic Tube Cutting Machine With Feeding System EC-830FS Tube Cutting Machine With Feeding System EC-3100 Automatic Cable and Tube Cutting Machine

EC-6100 Automatic Heat Shrink Tube Cutting Machine EC-6800 Automatic Cutting Machine EC-6100H Automatic Hot Cutting Machine EC-830 Corrugated Tube Cutting Machine EC-6500 Automatic Cable and Tube Cutting Machine EC-810 Automatic Cable Cutting Machine EC-850X Automatic Rotary Cutting Machine EC-821 Corrugated Tube Cutting Machine EC-890 Multifunctional Automatic Cutting Machine EC-870 High-power Automatic Tube Cutting Machine EC-816 Automatic Cutting Machine EC-823 High Speed Cutting Machine EC-805 Automatic Cable Cutting Machine EC-860 Corrugated Tube Cutting Machine EC-830F Automatic Tube Cutting Machine With Feeding System EC-830FS Tube Cutting Machine With Feeding System EC-3100 Automatic Cable and Tube Cutting Machine CS-4507/6010 Multifunctional Wire Stripping Machine UniStrip 2016 Pneumatic Wire Stripping Machine UniStrip 2018E Electric Cable Wire Stripping Machine CS-5507 Automatic coaxial cable stripping machine CS-5515 Automatic coaxial cable stripping machine CS-400 Braided Shield Cable Stripping Machine CS Series Rotary Cable Stripping Machine CS-2486 Coaxial Cable Wire Stripping Machine

CS-4507/6010 Multifunctional Wire Stripping Machine UniStrip 2016 Pneumatic Wire Stripping Machine UniStrip 2018E Electric Cable Wire Stripping Machine CS-5507 Automatic coaxial cable stripping machine CS-5515 Automatic coaxial cable stripping machine CS-400 Braided Shield Cable Stripping Machine CS Series Rotary Cable Stripping Machine CS-2486 Coaxial Cable Wire Stripping Machine TM-20 Terminal Crimping Machine TM-20S Automatic Wire Terminal Crimping Machine TM-200 Terminal Crimping Machine TM-10P Registered Jack Crimping Machine TM-E140 Pre-insulation Ferrule Terminal Strip And Crimp Machine TM-E140S Automatic Wire Stripping Ferrule Crimping Machine TM-P300 Pneumatic Terminal Crimping Machine TM-E116 Electric Terminal Crimping Machine TM-P120 Pneumatic Terminal Crimping Machine SAT-AS6P Pneumatic Crimping Applicator SAT-MS6 Mechanical Crimping Applicator Side Feed Terminal Crimping Applicator Rear Feed Terminal Crimping Applicator Flag Terminal Crimping Applicator Crimp Applicator for Insulated Terminals TM-T Series Intelligent Servo Terminal Crimping Machine SAT-MS5 OTP Mechanical Applicator TM-25M Automatic Terminal Crimping Machine TM-FK40 Terminal Crimping Machine TM-CS6 Ultra Silent Copper Belt Crimping Machine

TM-20 Terminal Crimping Machine TM-20S Automatic Wire Terminal Crimping Machine TM-200 Terminal Crimping Machine TM-10P Registered Jack Crimping Machine TM-E140 Pre-insulation Ferrule Terminal Strip And Crimp Machine TM-E140S Automatic Wire Stripping Ferrule Crimping Machine TM-P300 Pneumatic Terminal Crimping Machine TM-E116 Electric Terminal Crimping Machine TM-P120 Pneumatic Terminal Crimping Machine SAT-AS6P Pneumatic Crimping Applicator SAT-MS6 Mechanical Crimping Applicator Side Feed Terminal Crimping Applicator Rear Feed Terminal Crimping Applicator Flag Terminal Crimping Applicator Crimp Applicator for Insulated Terminals TM-T Series Intelligent Servo Terminal Crimping Machine SAT-MS5 OTP Mechanical Applicator TM-25M Automatic Terminal Crimping Machine TM-FK40 Terminal Crimping Machine TM-CS6 Ultra Silent Copper Belt Crimping Machine ESC-BX1 Wire Cutting and Stripping Machine ESC-BX4 Wire Cutting And Stripping Machine ESC-BX30 Automatic Large Cable Cutting and Stripping Machine ESC-BX30S Sheathed Cable Automatic Cutting and Stripping Machine ESC-BXR Automatic Rotary Cable Stripping Machine ESC-BX6 Wire Cutting And Stripping Machine ESC-BX7 Wire Cutting And Stripping Machine ESC-BX8S Sheath Cable Cutting and Stripping Machine ESC-BX8PR Wire Cutting And Stripping Machine ESC-BX9 Automatic Cut and Strip Machine ESC-BX30SC Automatic Cable Wire Cutting and Stripping Machine ESC-BX120 Automatic Cutting and Stripping Machine ESC-BX30RS Multi-function Rotary Cable Stripping Machine ESC-BX120S Multi-core Cable Cutting and Stripping Machine ESC-BX60 Automatic Cable Cutting and Stripping Machine CS-9580 Automatic Coaxial Cable Stripping Machine CS-9680 Automatic Coaxial Cable Stripping Machine ESC-BX300 Automatic Cable Wire Cutting And Stripping Machine ESC-BX16 Wire Cutting Stripping Machine ESC-BX20SF Flat Twin Wire Cutting and Stripping Machine

ESC-BX1 Wire Cutting and Stripping Machine ESC-BX4 Wire Cutting And Stripping Machine ESC-BX30 Automatic Large Cable Cutting and Stripping Machine ESC-BX30S Sheathed Cable Automatic Cutting and Stripping Machine ESC-BXR Automatic Rotary Cable Stripping Machine ESC-BX6 Wire Cutting And Stripping Machine ESC-BX7 Wire Cutting And Stripping Machine ESC-BX8S Sheath Cable Cutting and Stripping Machine ESC-BX8PR Wire Cutting And Stripping Machine ESC-BX9 Automatic Cut and Strip Machine ESC-BX30SC Automatic Cable Wire Cutting and Stripping Machine ESC-BX120 Automatic Cutting and Stripping Machine ESC-BX30RS Multi-function Rotary Cable Stripping Machine ESC-BX120S Multi-core Cable Cutting and Stripping Machine ESC-BX60 Automatic Cable Cutting and Stripping Machine CS-9580 Automatic Coaxial Cable Stripping Machine CS-9680 Automatic Coaxial Cable Stripping Machine ESC-BX300 Automatic Cable Wire Cutting And Stripping Machine ESC-BX16 Wire Cutting Stripping Machine ESC-BX20SF Flat Twin Wire Cutting and Stripping Machine TM-200SC Automatic Strip and Weather Pack Terminal Crimp Machine TM-20SCM Automatic Cable Stripping and Crimping Machine TM-80SCS Servo Stripping and Crimping Machine TM-30SC Stripping and Crimping Machine TM-15SCE Electric Stripping and Crimping Machine TM-20SCS Servo Stripping and Crimping Machine TM-15SC Stripping and Crimping Machine

TM-200SC Automatic Strip and Weather Pack Terminal Crimp Machine TM-20SCM Automatic Cable Stripping and Crimping Machine TM-80SCS Servo Stripping and Crimping Machine TM-30SC Stripping and Crimping Machine TM-15SCE Electric Stripping and Crimping Machine TM-20SCS Servo Stripping and Crimping Machine TM-15SC Stripping and Crimping Machine ACC-101 Automatic Single-head Terminal Crimping Machine ACC-102A Fully Automatic Terminal Crimping Machine (Both Ends) ACC-102B Automatic Double Terminal Crimping Machine ACC-105 Fully Automatic Single-head End-dipping Tin Machine ACC-106 Fully Automatic 5-Wire Single-head End-dipping Tin Machine ACC-202UP Fully-automatic cut,strip,crimp,insert and Heat Heat-shrink tube machine ACC-308 (Both ends) Full automatic Soldering machine ACC-208 Fully Automatic Crimping Machine (Both Ends) ACC-508 Fully Automatic Twisting, Soldering and Crimping Machine ACC-608 Fully Automatic Flat Cable Cut Strip and Crimp Machine

ACC-101 Automatic Single-head Terminal Crimping Machine ACC-102A Fully Automatic Terminal Crimping Machine (Both Ends) ACC-102B Automatic Double Terminal Crimping Machine ACC-105 Fully Automatic Single-head End-dipping Tin Machine ACC-106 Fully Automatic 5-Wire Single-head End-dipping Tin Machine ACC-202UP Fully-automatic cut,strip,crimp,insert and Heat Heat-shrink tube machine ACC-308 (Both ends) Full automatic Soldering machine ACC-208 Fully Automatic Crimping Machine (Both Ends) ACC-508 Fully Automatic Twisting, Soldering and Crimping Machine ACC-608 Fully Automatic Flat Cable Cut Strip and Crimp Machine HSM-60 Heat Shrink Tube Processing Machine HSM-70 Heat Shrink Tube Processing Machine HSM-80B Heat Shrink Tube Processing Machine HSM-90 Heat Shrink Tube Processing Machine HSM-25M Heat Shrink Tube Processing Machine HSM-120 Heat Shrink Tube Heating Machine HSM-50 Heat Shrink Tube Processing Machine HSM-160 Heat Shrink Tube Processing Machine HSM-80A Heat Shrink Tube Heating Machine HSM-260E Enclosed Heat Shrink Tube Processing Machine HSM-260O Open Heat Shrink Tube Processing Machine HSM-20 Intelligent Heat Shrink Tube Processing Machine

HSM-60 Heat Shrink Tube Processing Machine HSM-70 Heat Shrink Tube Processing Machine HSM-80B Heat Shrink Tube Processing Machine HSM-90 Heat Shrink Tube Processing Machine HSM-25M Heat Shrink Tube Processing Machine HSM-120 Heat Shrink Tube Heating Machine HSM-50 Heat Shrink Tube Processing Machine HSM-160 Heat Shrink Tube Processing Machine HSM-80A Heat Shrink Tube Heating Machine HSM-260E Enclosed Heat Shrink Tube Processing Machine HSM-260O Open Heat Shrink Tube Processing Machine HSM-20 Intelligent Heat Shrink Tube Processing Machine HV-CS 9070 High-Voltage Cable Shield Cutting Machine HV-FS 9053 Cable Shield Folding Machine HV-ACS 9100 Cable Shield Processing Machine HV-ACS 9200 Automatic Cable Shield Processing System HV-ACS 9300 Automotive High Voltage Cable Processing Machine HV-ACS 9500 High Voltage Cable Processing Machine HV-FC 9312 Aluminum Foil Cutting Machine HV-CS 9120 Cable Stripping Machine

HV-CS 9070 High-Voltage Cable Shield Cutting Machine HV-FS 9053 Cable Shield Folding Machine HV-ACS 9100 Cable Shield Processing Machine HV-ACS 9200 Automatic Cable Shield Processing System HV-ACS 9300 Automotive High Voltage Cable Processing Machine HV-ACS 9500 High Voltage Cable Processing Machine HV-FC 9312 Aluminum Foil Cutting Machine HV-CS 9120 Cable Stripping Machine STB-10 Automatic Tape Bundling Machine STB-50 Desktop Bundling Machine STB-60 Adhesive Tape Bundling Machine STB-55 Desktop Tape Bundling Machine STB-50C Automatic Tape Cutting Machine STP-B Hand-held Taping Machine STP-F Hand-held Lithium Battery Tape Wrapping Machine STP-C Automatic Wire Taping Machine STP-D Automatic Tape Wrapping Machine STP-AS Automatic Tape bundling Machine

STB-10 Automatic Tape Bundling Machine STB-50 Desktop Bundling Machine STB-60 Adhesive Tape Bundling Machine STB-55 Desktop Tape Bundling Machine STB-50C Automatic Tape Cutting Machine STP-B Hand-held Taping Machine STP-F Hand-held Lithium Battery Tape Wrapping Machine STP-C Automatic Wire Taping Machine STP-D Automatic Tape Wrapping Machine STP-AS Automatic Tape bundling Machine CB-B15 Automatic Wiring Winding Machine CB-BT15 Automatic Wiring Winding Binding Machine CB-F30/150MCS Automatic Wiring Winding Machine CB-F30/150MCST18-45 Automatic Wiring Winding Binding Machine CB-F30/150MCST40-80 Automatic Wiring Winding Binding Machine CB-B15CST Automatic Wiring Coiling Binding Machine CB-F500MCS Automatic Wiring Winding Machine CB-B30/150CS Automatic Wiring Winding Machine CB-B10/15CS Automatic Wiring Winding Machine CB-WT630 Automatic Wire Winding and Tying Machine

CB-B15 Automatic Wiring Winding Machine CB-BT15 Automatic Wiring Winding Binding Machine CB-F30/150MCS Automatic Wiring Winding Machine CB-F30/150MCST18-45 Automatic Wiring Winding Binding Machine CB-F30/150MCST40-80 Automatic Wiring Winding Binding Machine CB-B15CST Automatic Wiring Coiling Binding Machine CB-F500MCS Automatic Wiring Winding Machine CB-B30/150CS Automatic Wiring Winding Machine CB-B10/15CS Automatic Wiring Winding Machine CB-WT630 Automatic Wire Winding and Tying Machine PF-08 Automatic Wire Prefeeder PF-30 Automatic Prefeeding Machine PF-60 Automatic Prefeeding Machine PF-150 Automatic Wire Prefeeding Machine CC-380 Cable Coiling Machine CC-680 Automatic Cable Coiling Machine CC-380D Cable Coil Machine PF-120 Large Automatic Wire Prefeeding Machine PF-90 Automatic Wire Prefeeder PF-100 Automatic Prefeeder PF-04 Automatic Wire Prefeeder PF-06 Automatic Wire Prefeeder PF-05 Automatic Wire Prefeeder

PF-08 Automatic Wire Prefeeder PF-30 Automatic Prefeeding Machine PF-60 Automatic Prefeeding Machine PF-150 Automatic Wire Prefeeding Machine CC-380 Cable Coiling Machine CC-680 Automatic Cable Coiling Machine CC-380D Cable Coil Machine PF-120 Large Automatic Wire Prefeeding Machine PF-90 Automatic Wire Prefeeder PF-100 Automatic Prefeeder PF-04 Automatic Wire Prefeeder PF-06 Automatic Wire Prefeeder PF-05 Automatic Wire Prefeeder

CHM-10 Crimp-Height Measurer PFM-220 Terminal Pulling Force Tester PFM-300 Terminal Pulling Force Tester PFM-200 Pull Force Tester For Wire Terminals TCA-120 Terminal Cross Section Analyzer TCA-120S Terminal Cross Section Analyzer TCA-150 Terminal Cross Section Analyzer PFM-50 Pull Force Measuring Machine

CHM-10 Crimp-Height Measurer PFM-220 Terminal Pulling Force Tester PFM-300 Terminal Pulling Force Tester PFM-200 Pull Force Tester For Wire Terminals TCA-120 Terminal Cross Section Analyzer TCA-120S Terminal Cross Section Analyzer TCA-150 Terminal Cross Section Analyzer PFM-50 Pull Force Measuring Machine