Application Analysis of Automobile Aluminum Power Cable

The high density and cost of traditional copper wires in automobiles have prompted the industry to seek alternative materials to achieve cost reduction and lightweighting. Aluminum has become an ideal substitute for copper due to its good conductivity, low density and low cost, but it also has problems such as low strength and easy oxidation. The article focuses on large-section automotive power cables, and deeply explores the technical difficulties that need to be solved when replacing copper with aluminum, including conductivity, strength, compressive creep, oxidation and differences in thermal expansion coefficients. By analyzing international automotive wire standards, a feasibility study on the replacement of copper with aluminum was conducted, and a specific technical solution was proposed: using 1 series pure aluminum wire with a larger cross-sectional area to replace copper wire, following the principle of equivalent resistance; providing two wire and terminal connection solutions: friction welding and ultrasonic welding, and using double-walled adhesive heat shrink tubing for sealing. The article provides a new path with reference value for automotive companies to achieve cost reduction and lightweighting.

Automotive wiring harnesses are all over the car body. Traditional wires are made of high-purity electrolytic copper forged, drawn and hinged by special processes. Due to the high density of copper, the total weight of the vehicle wiring harness exceeds 20kg and the cost is high, which brings cost pressure to enterprises. To this end, the industry is actively exploring alternative materials for copper wires to achieve the goals of cost reduction and lightweighting. Among common conductor materials, aluminum is an ideal substitute. It has good conductivity, second only to copper among commonly used metals, and is light in weight. Its density is about 30% of copper and its cost is only 20%~30% of copper, but it has problems such as low strength and easy oxidation. This article proposes a reference technical solution for replacing copper with aluminum for large-section automotive power cables.

1.Technical issues that need to be solved when replacing copper with aluminum

Aluminum is superior to copper in cost and quality, and has become a hot spot for cost reduction and lightweight research in automobile companies. However, aluminum replacing copper still faces some technical difficulties.

1) Aluminum's conductivity is inferior to copper. If the problem is solved by increasing the cross-sectional area of aluminum wire, the aluminum wire specification needs to be increased by 1~2 levels, which will make the aluminum wire harness larger than the copper wire harness. The installation space and bending radius need to be considered when arranging the harness.

2) Aluminum has low strength. The mechanical strength is only 1/3 of that of copper, and it is easy to be broken during crimping. When the car is driving, the wire vibrates and it is easy to break, so the strength of the aluminum wire needs to be increased.

3) Aluminum has significant compressive creep phenomenon. At around 80℃, the creep intensifies under pressure, while copper needs to be above 230℃ to show a certain degree of compressive creep. The compressive creep characteristics of aluminum will cause the connection point to loosen with temperature changes and time after the terminal is crimped, affecting the electrical performance of the wire.

Therefore, aluminum-copper connection technology requires special design to ensure reliable electrical performance throughout the product life cycle.

4) Aluminum is chemically active. It is easily oxidized when exposed to air, forming a dense and hard aluminum oxide film. Aluminum oxide has strong insulation properties and will affect the conductivity of aluminum wires. When aluminum contacts copper terminals in a humid and energized environment, it is easy to form a galvanic reaction, causing electrochemical corrosion at the connection and corroding the aluminum conductor. This situation must be avoided.

5) Aluminum and copper have different thermal expansion coefficients. After long-term alternation of hot and cold, the connection is easy to loosen, affecting the reliability of the connection point.

2.Feasibility analysis and technical solutions of aluminum replacing copper

1) Feasibility analysis

Internationally, there are three main automotive wire standards: American, Japanese, and European. With the global integration of industrial technology in the automotive industry, the wire standards of various countries are gradually moving closer to the ISO series of international standards. At present, most domestic automobile OEMs use copper core wires and follow the ISO 19642-5 and ISO 6722-1 international standards. These two standards have similar technical requirements for automotive copper core wires, and both specify the resistivity, withstand voltage and other characteristics of the wires in detail. Among them, ISO 19642-5 has more detailed requirements for wire performance.

Foreign aluminum wires have been used in industrial applications for at least 30 years. They were first used in the aviation industry and began to be used in the automotive field in the early 21st century. In 2013, the official international standard ISO 6722-2 for automotive aluminum wires was released, and in 2019, the similar ISO 19642-6 was released. International standards ISO 19642-6 and ISO 6722-2 provide technical requirements for conductor diameter, resistance, insulation volume resistivity, etc. The two standards are similar in content, and ISO 19642-6 has more detailed requirements for the performance of automotive aluminum conductors. Therefore, the design of the scheme needs to comprehensively consider these two international standards.

Aluminum conductors must be equivalent to copper conductors and meet three points: first, they must ensure that they have similar conductivity and other properties to the replaced copper conductors, ensuring that the original circuit function is basically maintained while replacing the conductor material; second, prevent the aluminum wire from being oxidized; third, achieve a reliable connection between the aluminum wire and the terminal, because the aluminum material has low hardness and may fatigue and break after bending, winding, and high-frequency vibration.

2) Alternatives for power line conductors

Comparing the international standards ISO 19642-5 and ISO 6722-1 for copper conductors, and ISO 19642-6 and ISO 6722-2 for aluminum conductors, it can be seen that when the resistance is similar, the aluminum conductor needs a larger specification to achieve a conductivity similar to that of the copper conductor.

The European aluminum and aluminum alloy composition standard EN 573-3:2003 stipulates that aluminum and aluminum alloys can be divided into 8 series. Among them, series 1 is pure aluminum wire with an aluminum content of more than 99%; series 2 to 8 aluminum alloys are new aluminum-based composite alloys developed by adding different proportions of Si, Fe, Cu, Mg, Mn, nano-ceramics and carbon nanomaterials to pure aluminum. The matrix is a heat-treated strengthened alloy. Under the condition of ensuring certain conductivity, the tensile strength of the aluminum alloy is maximized, while ensuring sufficient elongation.

The characteristics of 1 series pure aluminum wire are high conductivity, good thermal conductivity, tensile strength of 60~110MPa, and conductor elongation greater than 12%. It is the most commonly used aluminum conductor for automotive cables. This grade of aluminum wire is suitable for large-diameter power cords.

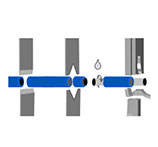

In summary, the principle of equivalent resistance can be followed to replace copper wire with pure aluminum wire with a larger cross-sectional area, and the resistance of the wires before and after replacement is the same or close. For example, the cross-sectional area of the original copper wire is 35mm2, and the maximum resistance of the conductor per unit length at 20℃ is 0.527mΩ/m. The aluminum conductor specification with the closest resistance parameter needs to be increased to 60mm2. At this time, the maximum resistance of the conductor per unit length at 20℃ is 0.525mΩ/m.

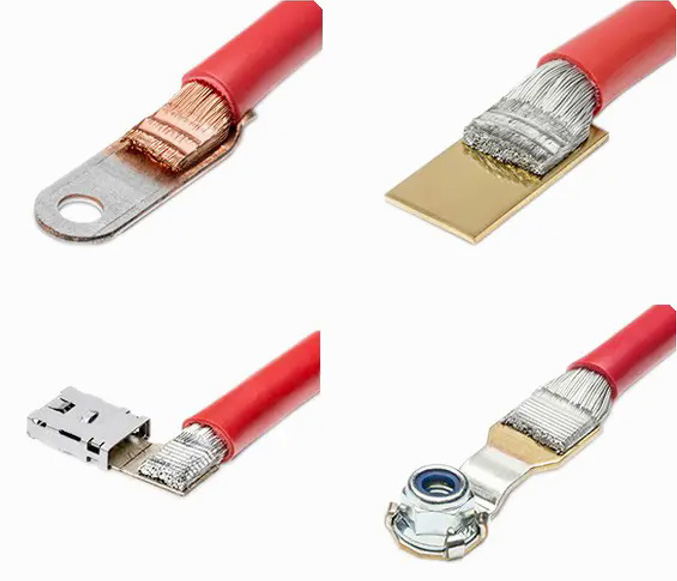

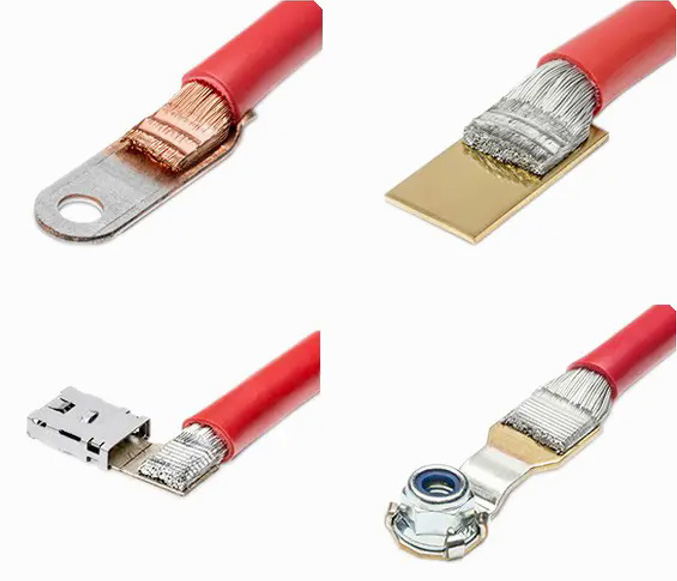

3) Connection scheme between wires and terminals

①Friction welding solution

Friction welding technology originated more than a hundred years ago. It uses the heat generated by the friction of the workpiece contact surface to make the workpiece plastically deform under pressure, thereby achieving welding. This technology is widely used in the civil and aerospace fields.

The equipment drives the workpiece to generate a lot of heat by friction, which reduces the hardness of the metal, improves the plasticity, and makes the metal atoms diffuse and cool and crystallize each other to form a firm friction welding joint. At the same time, high-speed friction destroys the oxide film on the metal surface and improves the conductivity of the welded joint. Compared with traditional fusion welding, friction welding has the following characteristics: First, the welded joint has high strength, stable quality, good component consistency, and the joint strength is equivalent to that of the parent material; second, it is energy-saving and environmentally friendly, without the need for welding rods and protective gases, no toxic or harmful gases are generated during the welding process, and the equipment consumes little power; third, friction welding can achieve the welding of dissimilar materials, the joint has no pores or inclusions, and no electrochemical corrosion occurs.

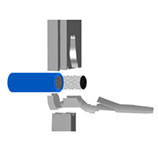

In this solution, the "L"-shaped copper-aluminum composite terminal adopts a rotary friction welding process to connect the end forged copper plate and the tail pure aluminum cylinder. The forged copper plate is used to assemble to the battery or starter. It is made of brass, has high strength, is not easy to break during installation, and the surface tinning can alleviate the electrochemical corrosion caused by the contact between the brass and the car body. The tail pure aluminum cylinder is a columnar hollow structure used to connect the aluminum conductor. After the aluminum conductor is placed into the pure aluminum cylinder by special equipment, it is crimped by forging equipment. The pure aluminum wire and the pure aluminum cylinder are made of the same material and have the same thermal expansion coefficient, which can avoid fatigue fracture when high and low temperatures alternate due to the difference in thermal expansion coefficient.

The advantages of this solution are: the forged copper plate can meet the assembly requirements, and the aluminum tube connecting the aluminum wire can avoid fatigue fracture caused by the different thermal expansion coefficients of the traditional copper terminal and the aluminum conductor, which not only solves the problem of terminal installation strength, but also solves the problem of connection between the aluminum conductor and the terminal.

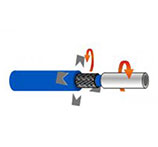

After the terminal is connected to the aluminum conductor, a double-walled heat shrink tube with glue can be used for sealing. The heat shrink tube has insulation, corrosion resistance and wear resistance. After being heated by special equipment, the outer wall shrinks, and the solid glue on the inner wall melts into liquid glue, covering the terminal connection part and the surface of the wire insulation skin. After cooling and solidification, it can achieve sealing and corrosion resistance, and prevent oxidation corrosion at the joint.

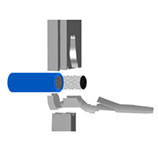

②Ultrasonic welding solution

Since the 1980s, ultrasonic metal welding technology has been applied to wire harness welding, using ultrasonic frequency vibration energy to reorganize the metal molecular lattice structure and connect the same or different metals. The welded joint achieves metallurgical bonding without melting the parent material, which belongs to solid-state welding and can effectively avoid the spatter and oxidation of ordinary welding.

Ultrasonic welding technology is widely used in the connection of wires and wires, wires and terminals. The welding process is rapid and the process parameters can be monitored throughout the process. The welded joint is a pure metal connector, which is not easily affected by aging, creep and fatigue. The connection is firm, the reliability is high, and the contact resistance is low.

This technology can connect the same or different materials, such as copper and aluminum. Since the metal is directly welded, no additional solder or flux is required. In addition, ultrasonic welding has low thermal stress on the material and basically does not change the properties of the welded material and the surrounding materials. Ultrasonic welding has a simple process, high joint strength, good conductivity, and a wide range of conductor specifications that can be welded. Conductors with a cross-sectional area of 160mm2 or even larger can be welded. Similar to friction welding technology, ultrasonic welding technology is suitable for the connection of dissimilar materials and forms, such as copper and aluminum, wire and plate, and is widely used in the wire and cable industry. Therefore, this solution uses brass terminals, which are connected to pure aluminum conductors through ultrasonic welding technology, and are crimped and fixed with claws at the ends of the terminals to enhance the reliability of the connection. Similarly, double-walled adhesive heat shrink tubing can be used to seal the connection to prevent oxidation corrosion at the joint.

3. Summary

Based on the current situation of high cost and heavy weight of automotive copper wires, this paper studies the performance standards of copper and aluminum wires, and proposes a technical solution for replacing copper wires with aluminum wires, providing a new way for enterprises to reduce costs and reduce weight.

EC-6100 Automatic Heat Shrink Tube Cutting Machine EC-6800 Automatic Cutting Machine EC-6100H Automatic Hot Cutting Machine EC-830 Corrugated Tube Cutting Machine EC-6500 Automatic Cable and Tube Cutting Machine EC-810 Automatic Cable Cutting Machine EC-850X Automatic Rotary Cutting Machine EC-821 Corrugated Tube Cutting Machine EC-890 Multifunctional Automatic Cutting Machine EC-870 High-power Automatic Tube Cutting Machine EC-816 Automatic Cutting Machine EC-823 High Speed Cutting Machine EC-805 Automatic Cable Cutting Machine EC-860 Corrugated Tube Cutting Machine EC-830F Automatic Tube Cutting Machine With Feeding System EC-830FS Tube Cutting Machine With Feeding System EC-3100 Automatic Cable and Tube Cutting Machine

EC-6100 Automatic Heat Shrink Tube Cutting Machine EC-6800 Automatic Cutting Machine EC-6100H Automatic Hot Cutting Machine EC-830 Corrugated Tube Cutting Machine EC-6500 Automatic Cable and Tube Cutting Machine EC-810 Automatic Cable Cutting Machine EC-850X Automatic Rotary Cutting Machine EC-821 Corrugated Tube Cutting Machine EC-890 Multifunctional Automatic Cutting Machine EC-870 High-power Automatic Tube Cutting Machine EC-816 Automatic Cutting Machine EC-823 High Speed Cutting Machine EC-805 Automatic Cable Cutting Machine EC-860 Corrugated Tube Cutting Machine EC-830F Automatic Tube Cutting Machine With Feeding System EC-830FS Tube Cutting Machine With Feeding System EC-3100 Automatic Cable and Tube Cutting Machine CS-4507/6010 Multifunctional Wire Stripping Machine UniStrip 2016 Pneumatic Wire Stripping Machine UniStrip 2018E Electric Cable Wire Stripping Machine CS-5507 Automatic coaxial cable stripping machine CS-5515 Automatic coaxial cable stripping machine CS-400 Braided Shield Cable Stripping Machine CS Series Rotary Cable Stripping Machine CS-2486 Coaxial Cable Wire Stripping Machine

CS-4507/6010 Multifunctional Wire Stripping Machine UniStrip 2016 Pneumatic Wire Stripping Machine UniStrip 2018E Electric Cable Wire Stripping Machine CS-5507 Automatic coaxial cable stripping machine CS-5515 Automatic coaxial cable stripping machine CS-400 Braided Shield Cable Stripping Machine CS Series Rotary Cable Stripping Machine CS-2486 Coaxial Cable Wire Stripping Machine TM-20 Terminal Crimping Machine TM-20S Automatic Wire Terminal Crimping Machine TM-200 Terminal Crimping Machine TM-10P Registered Jack Crimping Machine TM-E140 Pre-insulation Ferrule Terminal Strip And Crimp Machine TM-E140S Automatic Wire Stripping Ferrule Crimping Machine TM-P300 Pneumatic Terminal Crimping Machine TM-E116 Electric Terminal Crimping Machine TM-P120 Pneumatic Terminal Crimping Machine SAT-AS6P Pneumatic Crimping Applicator SAT-MS6 Mechanical Crimping Applicator Side Feed Terminal Crimping Applicator Rear Feed Terminal Crimping Applicator Flag Terminal Crimping Applicator Crimp Applicator for Insulated Terminals TM-T Series Intelligent Servo Terminal Crimping Machine SAT-MS5 OTP Mechanical Applicator TM-25M Automatic Terminal Crimping Machine TM-FK40 Terminal Crimping Machine TM-CS6 Ultra Silent Copper Belt Crimping Machine

TM-20 Terminal Crimping Machine TM-20S Automatic Wire Terminal Crimping Machine TM-200 Terminal Crimping Machine TM-10P Registered Jack Crimping Machine TM-E140 Pre-insulation Ferrule Terminal Strip And Crimp Machine TM-E140S Automatic Wire Stripping Ferrule Crimping Machine TM-P300 Pneumatic Terminal Crimping Machine TM-E116 Electric Terminal Crimping Machine TM-P120 Pneumatic Terminal Crimping Machine SAT-AS6P Pneumatic Crimping Applicator SAT-MS6 Mechanical Crimping Applicator Side Feed Terminal Crimping Applicator Rear Feed Terminal Crimping Applicator Flag Terminal Crimping Applicator Crimp Applicator for Insulated Terminals TM-T Series Intelligent Servo Terminal Crimping Machine SAT-MS5 OTP Mechanical Applicator TM-25M Automatic Terminal Crimping Machine TM-FK40 Terminal Crimping Machine TM-CS6 Ultra Silent Copper Belt Crimping Machine ESC-BX1 Wire Cutting and Stripping Machine ESC-BX4 Wire Cutting And Stripping Machine ESC-BX30 Automatic Large Cable Cutting and Stripping Machine ESC-BX30S Sheathed Cable Automatic Cutting and Stripping Machine ESC-BXR Automatic Rotary Cable Stripping Machine ESC-BX6 Wire Cutting And Stripping Machine ESC-BX7 Wire Cutting And Stripping Machine ESC-BX8S Sheath Cable Cutting and Stripping Machine ESC-BX8PR Wire Cutting And Stripping Machine ESC-BX9 Automatic Cut and Strip Machine ESC-BX30SC Automatic Cable Wire Cutting and Stripping Machine ESC-BX120 Automatic Cutting and Stripping Machine ESC-BX30RS Multi-function Rotary Cable Stripping Machine ESC-BX120S Multi-core Cable Cutting and Stripping Machine ESC-BX60 Automatic Cable Cutting and Stripping Machine CS-9580 Automatic Coaxial Cable Stripping Machine CS-9680 Automatic Coaxial Cable Stripping Machine ESC-BX300 Automatic Cable Wire Cutting And Stripping Machine ESC-BX16 Wire Cutting Stripping Machine ESC-BX20SF Flat Twin Wire Cutting and Stripping Machine

ESC-BX1 Wire Cutting and Stripping Machine ESC-BX4 Wire Cutting And Stripping Machine ESC-BX30 Automatic Large Cable Cutting and Stripping Machine ESC-BX30S Sheathed Cable Automatic Cutting and Stripping Machine ESC-BXR Automatic Rotary Cable Stripping Machine ESC-BX6 Wire Cutting And Stripping Machine ESC-BX7 Wire Cutting And Stripping Machine ESC-BX8S Sheath Cable Cutting and Stripping Machine ESC-BX8PR Wire Cutting And Stripping Machine ESC-BX9 Automatic Cut and Strip Machine ESC-BX30SC Automatic Cable Wire Cutting and Stripping Machine ESC-BX120 Automatic Cutting and Stripping Machine ESC-BX30RS Multi-function Rotary Cable Stripping Machine ESC-BX120S Multi-core Cable Cutting and Stripping Machine ESC-BX60 Automatic Cable Cutting and Stripping Machine CS-9580 Automatic Coaxial Cable Stripping Machine CS-9680 Automatic Coaxial Cable Stripping Machine ESC-BX300 Automatic Cable Wire Cutting And Stripping Machine ESC-BX16 Wire Cutting Stripping Machine ESC-BX20SF Flat Twin Wire Cutting and Stripping Machine TM-200SC Automatic Strip and Weather Pack Terminal Crimp Machine TM-20SCM Automatic Cable Stripping and Crimping Machine TM-80SCS Servo Stripping and Crimping Machine TM-30SC Stripping and Crimping Machine TM-15SCE Electric Stripping and Crimping Machine TM-20SCS Servo Stripping and Crimping Machine TM-15SC Stripping and Crimping Machine

TM-200SC Automatic Strip and Weather Pack Terminal Crimp Machine TM-20SCM Automatic Cable Stripping and Crimping Machine TM-80SCS Servo Stripping and Crimping Machine TM-30SC Stripping and Crimping Machine TM-15SCE Electric Stripping and Crimping Machine TM-20SCS Servo Stripping and Crimping Machine TM-15SC Stripping and Crimping Machine ACC-101 Automatic Single-head Terminal Crimping Machine ACC-102A Fully Automatic Terminal Crimping Machine (Both Ends) ACC-102B Automatic Double Terminal Crimping Machine ACC-105 Fully Automatic Single-head End-dipping Tin Machine ACC-106 Fully Automatic 5-Wire Single-head End-dipping Tin Machine ACC-202UP Fully-automatic cut,strip,crimp,insert and Heat Heat-shrink tube machine ACC-308 (Both ends) Full automatic Soldering machine ACC-208 Fully Automatic Crimping Machine (Both Ends) ACC-508 Fully Automatic Twisting, Soldering and Crimping Machine ACC-608 Fully Automatic Flat Cable Cut Strip and Crimp Machine

ACC-101 Automatic Single-head Terminal Crimping Machine ACC-102A Fully Automatic Terminal Crimping Machine (Both Ends) ACC-102B Automatic Double Terminal Crimping Machine ACC-105 Fully Automatic Single-head End-dipping Tin Machine ACC-106 Fully Automatic 5-Wire Single-head End-dipping Tin Machine ACC-202UP Fully-automatic cut,strip,crimp,insert and Heat Heat-shrink tube machine ACC-308 (Both ends) Full automatic Soldering machine ACC-208 Fully Automatic Crimping Machine (Both Ends) ACC-508 Fully Automatic Twisting, Soldering and Crimping Machine ACC-608 Fully Automatic Flat Cable Cut Strip and Crimp Machine HSM-60 Heat Shrink Tube Processing Machine HSM-70 Heat Shrink Tube Processing Machine HSM-80B Heat Shrink Tube Processing Machine HSM-90 Heat Shrink Tube Processing Machine HSM-25M Heat Shrink Tube Processing Machine HSM-120 Heat Shrink Tube Heating Machine HSM-50 Heat Shrink Tube Processing Machine HSM-160 Heat Shrink Tube Processing Machine HSM-80A Heat Shrink Tube Heating Machine HSM-260E Enclosed Heat Shrink Tube Processing Machine HSM-260O Open Heat Shrink Tube Processing Machine HSM-20 Intelligent Heat Shrink Tube Processing Machine

HSM-60 Heat Shrink Tube Processing Machine HSM-70 Heat Shrink Tube Processing Machine HSM-80B Heat Shrink Tube Processing Machine HSM-90 Heat Shrink Tube Processing Machine HSM-25M Heat Shrink Tube Processing Machine HSM-120 Heat Shrink Tube Heating Machine HSM-50 Heat Shrink Tube Processing Machine HSM-160 Heat Shrink Tube Processing Machine HSM-80A Heat Shrink Tube Heating Machine HSM-260E Enclosed Heat Shrink Tube Processing Machine HSM-260O Open Heat Shrink Tube Processing Machine HSM-20 Intelligent Heat Shrink Tube Processing Machine HV-CS 9070 High-Voltage Cable Shield Cutting Machine HV-FS 9053 Cable Shield Folding Machine HV-ACS 9100 Cable Shield Processing Machine HV-ACS 9200 Automatic Cable Shield Processing System HV-ACS 9300 Automotive High Voltage Cable Processing Machine HV-ACS 9500 High Voltage Cable Processing Machine HV-FC 9312 Aluminum Foil Cutting Machine HV-CS 9120 Cable Stripping Machine

HV-CS 9070 High-Voltage Cable Shield Cutting Machine HV-FS 9053 Cable Shield Folding Machine HV-ACS 9100 Cable Shield Processing Machine HV-ACS 9200 Automatic Cable Shield Processing System HV-ACS 9300 Automotive High Voltage Cable Processing Machine HV-ACS 9500 High Voltage Cable Processing Machine HV-FC 9312 Aluminum Foil Cutting Machine HV-CS 9120 Cable Stripping Machine STB-10 Automatic Tape Bundling Machine STB-50 Desktop Bundling Machine STB-60 Adhesive Tape Bundling Machine STB-55 Desktop Tape Bundling Machine STB-50C Automatic Tape Cutting Machine STP-B Hand-held Taping Machine STP-F Hand-held Lithium Battery Tape Wrapping Machine STP-C Automatic Wire Taping Machine STP-D Automatic Tape Wrapping Machine STP-AS Automatic Tape bundling Machine

STB-10 Automatic Tape Bundling Machine STB-50 Desktop Bundling Machine STB-60 Adhesive Tape Bundling Machine STB-55 Desktop Tape Bundling Machine STB-50C Automatic Tape Cutting Machine STP-B Hand-held Taping Machine STP-F Hand-held Lithium Battery Tape Wrapping Machine STP-C Automatic Wire Taping Machine STP-D Automatic Tape Wrapping Machine STP-AS Automatic Tape bundling Machine CB-B15 Automatic Wiring Winding Machine CB-BT15 Automatic Wiring Winding Binding Machine CB-F30/150MCS Automatic Wiring Winding Machine CB-F30/150MCST18-45 Automatic Wiring Winding Binding Machine CB-F30/150MCST40-80 Automatic Wiring Winding Binding Machine CB-B15CST Automatic Wiring Coiling Binding Machine CB-F500MCS Automatic Wiring Winding Machine CB-B30/150CS Automatic Wiring Winding Machine CB-B10/15CS Automatic Wiring Winding Machine CB-WT630 Automatic Wire Winding and Tying Machine

CB-B15 Automatic Wiring Winding Machine CB-BT15 Automatic Wiring Winding Binding Machine CB-F30/150MCS Automatic Wiring Winding Machine CB-F30/150MCST18-45 Automatic Wiring Winding Binding Machine CB-F30/150MCST40-80 Automatic Wiring Winding Binding Machine CB-B15CST Automatic Wiring Coiling Binding Machine CB-F500MCS Automatic Wiring Winding Machine CB-B30/150CS Automatic Wiring Winding Machine CB-B10/15CS Automatic Wiring Winding Machine CB-WT630 Automatic Wire Winding and Tying Machine PF-08 Automatic Wire Prefeeder PF-30 Automatic Prefeeding Machine PF-60 Automatic Prefeeding Machine PF-150 Automatic Wire Prefeeding Machine CC-380 Cable Coiling Machine CC-680 Automatic Cable Coiling Machine CC-380D Cable Coil Machine PF-120 Large Automatic Wire Prefeeding Machine PF-90 Automatic Wire Prefeeder PF-100 Automatic Prefeeder PF-04 Automatic Wire Prefeeder PF-06 Automatic Wire Prefeeder PF-05 Automatic Wire Prefeeder

PF-08 Automatic Wire Prefeeder PF-30 Automatic Prefeeding Machine PF-60 Automatic Prefeeding Machine PF-150 Automatic Wire Prefeeding Machine CC-380 Cable Coiling Machine CC-680 Automatic Cable Coiling Machine CC-380D Cable Coil Machine PF-120 Large Automatic Wire Prefeeding Machine PF-90 Automatic Wire Prefeeder PF-100 Automatic Prefeeder PF-04 Automatic Wire Prefeeder PF-06 Automatic Wire Prefeeder PF-05 Automatic Wire Prefeeder

CHM-10 Crimp-Height Measurer PFM-220 Terminal Pulling Force Tester PFM-300 Terminal Pulling Force Tester PFM-200 Pull Force Tester For Wire Terminals TCA-120 Terminal Cross Section Analyzer TCA-120S Terminal Cross Section Analyzer TCA-150 Terminal Cross Section Analyzer PFM-50 Pull Force Measuring Machine

CHM-10 Crimp-Height Measurer PFM-220 Terminal Pulling Force Tester PFM-300 Terminal Pulling Force Tester PFM-200 Pull Force Tester For Wire Terminals TCA-120 Terminal Cross Section Analyzer TCA-120S Terminal Cross Section Analyzer TCA-150 Terminal Cross Section Analyzer PFM-50 Pull Force Measuring Machine